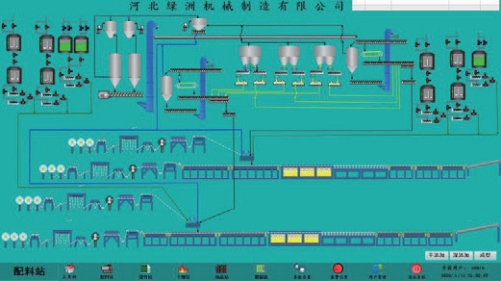

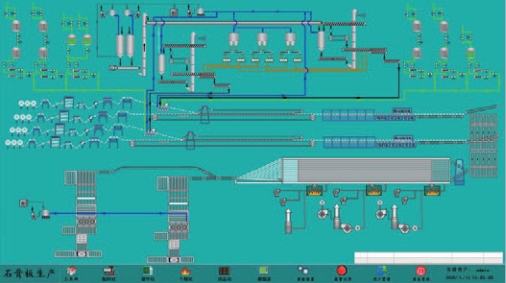

目(mu)前(qian)國(guo)內無紙面(mian)(mian)石膏板生產線的(de)自(zi)(zi)動(dong)(dong)(dong)(dong)化程度(du)(du)還未實(shi)(shi)現,現處(chu)于手(shou)動(dong)(dong)(dong)(dong)和(he)(he)半自(zi)(zi)動(dong)(dong)(dong)(dong)水平,受(shou)自(zi)(zi)動(dong)(dong)(dong)(dong)化水平的(de)限制(zhi)(zhi)(zhi),國(guo)內的(de)無紙面(mian)(mian)石膏板的(de)質量(liang)(liang)和(he)(he)產量(liang)(liang)均(jun)不能滿足(zu)市場的(de)需求;為了(le)解決以上存在的(de)問題,本設(she)備(bei)提供(gong)了(le)一套(tao)自(zi)(zi)動(dong)(dong)(dong)(dong)控(kong)(kong)(kong)制(zhi)(zhi)(zhi)系(xi)統;其所采(cai)用(yong)(yong)的(de)方案是:該自(zi)(zi)控(kong)(kong)(kong)系(xi)統包(bao)括(kuo)中(zhong)(zhong)央(yang)控(kong)(kong)(kong)制(zhi)(zhi)(zhi)室、溫度(du)(du)控(kong)(kong)(kong)制(zhi)(zhi)(zhi)站、配料工(gong)作(zuo)(zuo)站、成(cheng)型工(gong)作(zuo)(zuo)站、切(qie)斷工(gong)作(zuo)(zuo)站、橫向(xiang)輸送工(gong)作(zuo)(zuo)站、烘干工(gong)作(zuo)(zuo)站、各個工(gong)作(zuo)(zuo)站之間通過(guo) MELSCNET/H 網(wang)(wang)絡(luo)(luo)系(xi)統環網(wang)(wang)連(lian)(lian)接,構成(cheng)控(kong)(kong)(kong)制(zhi)(zhi)(zhi)網(wang)(wang)絡(luo)(luo)層;各工(gong)作(zuo)(zuo)站通過(guo) CC-LINK 網(wang)(wang)與智能控(kong)(kong)(kong)制(zhi)(zhi)(zhi)設(she)備(bei)、變頻(pin)器連(lian)(lian)接,構成(cheng)現場網(wang)(wang)絡(luo)(luo)層;生產控(kong)(kong)(kong)制(zhi)(zhi)(zhi)采(cai)用(yong)(yong)分(fen)布式(shi) PLC 控(kong)(kong)(kong)制(zhi)(zhi)(zhi)系(xi)統, CPU 模(mo)塊選用(yong)(yong)西門子(zi) S7-300,現場I/O 模(mo)塊采(cai)用(yong)(yong)西門子(zi) ET-200S,人機(ji)界面(mian)(mian) HMI 為西門子(zi) WinCC。各控(kong)(kong)(kong)制(zhi)(zhi)(zhi)站和(he)(he)上位控(kong)(kong)(kong)制(zhi)(zhi)(zhi)中(zhong)(zhong)心 SCADA 通過(guo)冗余(yu)工(gong)業以太網(wang)(wang)相連(lian)(lian),從而實(shi)(shi)現生產過(guo)程的(de)集中(zhong)(zhong)控(kong)(kong)(kong)制(zhi)(zhi)(zhi)和(he)(he)實(shi)(shi)時數據統一管理(li)。設(she)備(bei)級(變頻(pin)器、分(fen)布式(shi) I/O 等)采(cai)用(yong)(yong)現場總線通訊。電氣控(kong)(kong)(kong)制(zhi)(zhi)(zhi)設(she)備(bei)主要包(bao)括(kuo) MCC 控(kong)(kong)(kong)制(zhi)(zhi)(zhi)柜(ju)、PLC 控(kong)(kong)(kong)制(zhi)(zhi)(zhi)柜(ju)、SCADA 操作(zuo)(zuo)員站、現場各類(lei)檢測元件。